Owning solar panels is a valuable investment that not only reduces your electricity bill, it also reduces your carbon footprint by providing you with renewable energy for the next 20-25 years. Even though solar panels require comparatively less maintenance when compared to other power electronic devices installed in your residence or factory due to lack of moving parts, regular maintenance is still required to ensure that your investment is reaping the maximum long-term benefits.

Understanding what kind of maintenance is required is an important thing to consider before scheduling a visit with your solar pv service provider. There are two kinds of maintenance activities that can be carried out on your solar pv system, namely, Preventive Maintenance and Corrective Maintenance. Preventive Maintenance refers to activities undertaken to keep the generation losses to a minimum. On the other hand, Corrective Maintenance corresponds to returning the PV system back to a functioning state once a failure has occurred.

Preventive Maintenance mainly consists of the cleaning of solar panels and the management of vegetation surrounding the panels.

Even though rains clear off debris and dust to a certain extent, dust and particles collect on the solar panel limiting the amount of sunlight directly hitting your solar panel. Therefore, it is suggested to clean the panels at least twice an year in rural areas and up to four times an year in areas of high dust accumulation.

Every once in a while, it is important to check if nearby trees have grown to such an extent that they cast a shadow on the panels, or if the near by branches are now lying on top of the panels. This can reduce generation drastically as the panels can be covered almost completely, bringing the output from these panels to almost zero. Solutions such as the SolarEdge Power Optimizer ensures maximum generation even from partial generation, but prevention is always better than cure. Ask your service team to check for shading from vegetation and have it cleared just enough to ensure that the panels will not be affected for the next year or so.

It is recommended to carry out preventive maintenance at regular pre-determined intervals so that the reduction in generation is kept at a minimum.

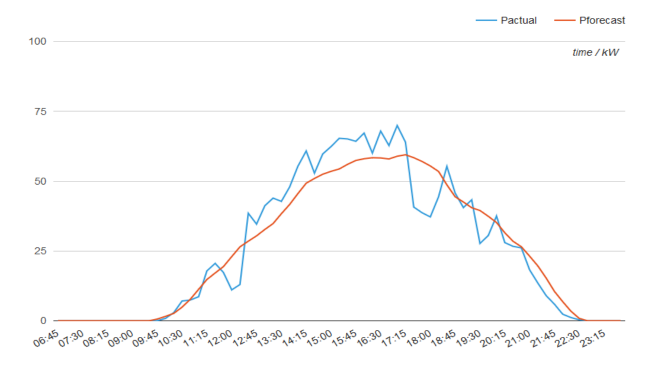

Corrective Maintenance on the other hand requires a team to visit your system only when a fault occurs. Failures of the solar pv system can be identified through the remote monitoring system provided by the inverter manufacturer or through onsite inspection during a panel service. The fault may occur on the panel, optimizer, inverter or grid connection point.

Onsite inspection, electrical system testing, fault diagnosis and part replacement are not usually covered by the OEM Equipment Manufacturer, but the replacements parts are usually covered if the warranty conditions are met.

At the end of the day, if you notice any irregularities on your electricity bill or an anomaly on your monitoring portal, contact your service provider to have a look and make sure everything is as it should be.

Recent Comments