Being an ever-evolving technology, solar photovoltaic technology has been giving birth to a number of different species of solar photovoltaics. The efficiency, durability, technical/ economic feasibility, payback time…. All depends on the type of solar cells.

Some are more efficient than others but not cost-effective. They are, of cause, ideal to power space satellites but not to offset your electricity bill. If used in terrestrial applications, it would cost an arm and a leg. Simply, they do not fit your rooftop or wallet. Out of hundreds, only a few types of photovoltaics have been commercialized because most of other PV technologies are still not technologically/ economically viable.

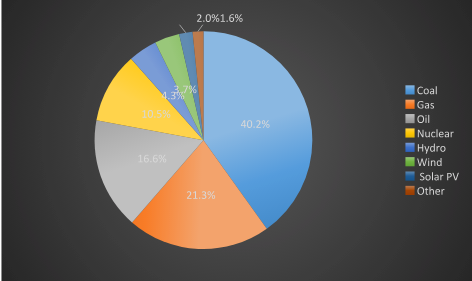

Figure 01: Market share (%) of different photovoltaic technologies in 2015 [1]

Above pie chart demonstrates the current market share of the most dominant photovoltaic technologies available in today’s market. As it can be seen, silicon-based solar photovoltaics make up almost 93% of the market whilst all other types of photovoltaics represent merely 7% of the market. No any other type of photovoltaics has come to win a minute or at least a second from the above chart!

Depending on the key materials used and level of commercial maturity of the technology, photovoltaic technologies are classified into three generations namely first, second, and third generations [2].

First generation solar cells

The first generation solar photovoltaics are well-matured in terms of their technology, and fabrication process. They represent the oldest commercially available photovoltaics technologies. Typically, they are made of either crystalline silicon (c-Si) or GaAs wafers.

GaAs is a direct bandgap semiconductor material with a bandgap of 1.43 eV at 300 K and exhibits remarkable optical properties compared to silicon. Silicon, on the other hand, is an indirect bandgap material whose bandgap is about 1.12 eV at 300 K [3]. Therefore, silicon solar cells require comparatively thicker silicon wafers in order to absorb incoming sunlight sufficiently.

Advantages of GaAs over c-Si

- Having a wide bandgap and outstanding optical properties, GaAs solar cells outperform much efficiently their crystalline silicon counterpart.

- GaAs solar cells require much less amount of semiconductor material than silicon solar cells do. This ability paves the way to manufacture lightweight, high-efficient solar cells.

- Performance of any photovoltaic technology drops with increasing temperature. But GaAs solar cells perform well even at higher temperatures since their temperature coefficient (A measure of performance loss with increasing temperature relative to 25˚ C) is impressively low. This distinctive characteristic makes them an ideal option for hot countries to minimize the energy loss of PVs.

- Unlike other photovoltaic technologies, GaAs solar cells can endure harsh environmental conditions like UV radiation and moisture.

- Electrons run much faster through the GaAs structure than they do through silicon. Simply, electron mobility in GaAs is much greater than in Si.

- GaAs solar cells possess a smaller short-circuit current density, a greater open-circuit voltage and a superior conversion efficiency than c-Si solar cells do.

c-Si or GaAs solar cells?

It is true that GaAs solar cells offer unparalleled benefits with the highest conversion efficiency of any photovoltaic material [4]. But still…They have not yet been chosen for commercial solar electricity generation purposes.

Why?

What are the factors hindering the commercial terrestrial applications of GaAs solar cells?

Well

Firstly, the GaAs solar cell manufacturing process is much expensive. Secondly, GaAs is a an expensive material than silicon since gallium and arsenic are a very rare materials on the earth’s crust. Another key point is that mass production of GaAs solar cells requires more and more gallium/ arsenic. Note that natural abundance of Si, Ga and As are 29.5%, 0.0019% and 0.00017%, respectively [5]! It is a big challenge to maintain a continuous supply in large-scale since both gallium and arsenic are rare/ expensive materials. Following chart clearly explains how rare materials arsenic and gallium are.

Figure 02: Natural abundance of Si, Ga and As [5]

Take a look at the above chart and see if you can observe any Ga or As.

You would see…

You can observe neither Ga nor As. You can observe Si, though.

It is evident that silicon is one of the most abundant element and thus is the best material for large-scale implementation. Moreover, arsenic has been identified to be a carcinogen. Inorganic arsenic (GaAs is partly dissociated in vivo into inorganic arsenic) can induce lung, skin, and bladder cancers [6]. In addition, it has been observed that arsenic is having a link with cardiac disorders, neurological diseases and even diabetes [7]. Some studies also suggest its relationships with some chronic diseases like acute kidney failure. Hence, large-scale implementation of GaAs solar cells might be a disaster unless they are not recycled properly after their end-of-life.

c-Si solar cells are less efficient than GaAs solar cells. But other advantages offered by c-Si solar cells far outweigh any drawbacks.

Conclusion

- Si is one of the most abundant elements on the Earth’s crust while Ga and As are rare elements. No doubt! c-Si solar cell industry will not have a raw material problem in future. Finding raw materials for GaAs solar cells, however, would be a huge problem in mass production lines.

- c-Si solar cells release a much smaller amount of toxic materials during and after their lifecycle than GaAs solar cells do.

- The last fact is the most important thing. c-Si solar cells are less efficient than GaAs solar cells but are much less expensive and economically viable. That is why we have never seen GaAs solar panels at least on a single rooftop while thousands of rooftops are using c-Si solar panels to generate clean electricity.

- c-Si solar cell technology is a proven, cost-effective way of generating electricity. Being a much expensive technology, GaAs solar cells cannot compete with the current c-Si solar cell technology.

Will GaAs solar cells be cost-effective? If so, when?

Nobody knows.

Anyway… We know one important thing!

c-Si solar cell technology has already proven to be cost-effective even in some snowy countries. And it is a God’s gift for Sunbelt countries!

References

[1] Tao M. Inorganic Photovoltaic Solar Cells: silicon and beyond. The Electrochemical Society Interface 2008:30–5

[2] Ranabhat, Kiran, et al. “An introduction to solar cell technology.” Journal of Applied Engineering Science 14.4 (2016): 481-491.

[3] Sze, S. M., & Irvin, J. C. (1968). Resistivity, mobility and impurity levels in GaAs, Ge, and Si at 300 K. Solid-State Electronics, 11 (6), 599-602.

[4] Jean, J., Brown, P. R., Jaffe, R. L., Buonassisi, T., & Bulović, V. (2015). Pathways for solar photovoltaics. Energy & Environmental Science, 8 (4), 1200-1219.

[5] Yaroshevsky, A. A. (2006). Abundances of chemical elements in the Earth’s crust. Geochemistry International, 44 (1), 48-55.

[6] Omura, M., Tanaka, A., Hirata, M., Zhao, M., Makita, Y., Inoue, N., & Ishinishi, N. (1996). Testicular toxicity of gallium arsenide, indium arsenide, and arsenic oxide in rats by repetitive intratracheal instillation. Toxicological Sciences, 32 (1), 72-78.

[7] Hong, Y. S., Song, K. H., & Chung, J. Y. (2014). Health effects of chronic arsenic exposure. Journal of preventive medicine and public health, 47 (5), 245.

Recent Comments